Введение: Роль поверхности в пронзительных украшениях

Когда дело доходит до пронзительных украшений, Дьявол действительно в деталях. Помимо материалов и дизайна, Качество отделки поверхности может сделать или сломать ювелирные изделия. Для импортеров, Оптовики, и студии, Обеспечение того, чтобы каждая произведение выглядело безупречно и хорошо работает, является ключом к завоеванию доверия клиентов и удовлетворенности. Отделка поверхности не только улучшает визуальную привлекательность ювелирных изделий, но и повышает его долговечность и совместимость с кожей.

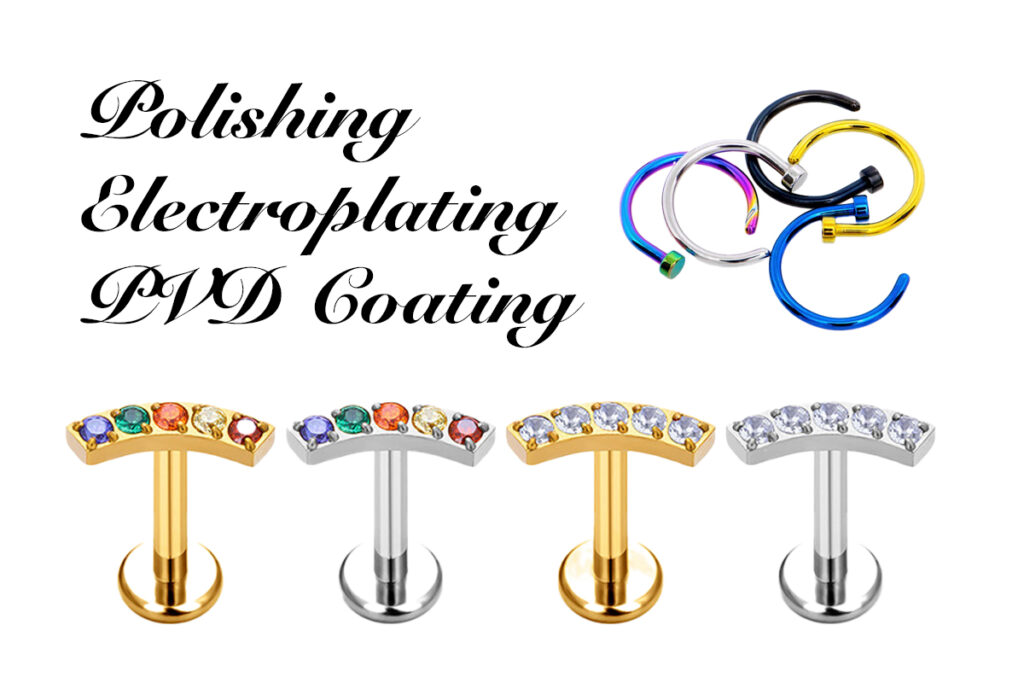

В этой статье, Мы рассмотрим три наиболее важных метода отделки поверхности в пронзительной ювелирной индустрии - полишись, гальванизация, и PVD -покрытие - и как они влияют на качество, производительность, и ценность ваших продуктов.

Основы методов отделки поверхности

Полировка

Полировка является одним из самых фундаментальных процессов отделки, используемых в производстве ювелирных изделий. Он включает в себя сглаживание поверхности украшений с использованием абразивных материалов или механических методов для удаления любых недостатков.

Ключевые преимущества полировки:

- Улучшенная эстетическая привлекательность: Полировка создает зеркальный блеск, Придавать ювелирные изделия премиум и привлекательный вид.

- Улучшенная безопасность кожи: Удаляя грубые края и микроатлеты, Полированные украшения на коже мягче, минимизация рисков раздражения.

- Более высокая воспринимаемая ценность: Безупречный, Полированная поверхность увеличивает воспринимаемое качество и цену украшений.

Методы полировки:

- Ручная полировка: Квалифицированные ремесленники используют полировочные колеса, соединения, и другие инструменты для достижения гладкой отделки.

- Автоматизированная полировка: Такие машины, как Tumblers и роботизированные полировки, используются для объемной продукции, обеспечение согласованности и эффективности.

Гальванизация

Обълектирование - это процесс покрытия основного металла с тонким слоем другого металла, такие как золото, родий, или серебро, через электрохимическую реакцию.

Ключевые преимущества гальванизации:

- Настройка цвета: Обълектирование обеспечивает широкий спектр цветов, от золота и серебра до розового золота и черного.

- Коррозионная стойкость: Шваблики с покрытием более устойчивы к пятном и ржавчине.

- Гипоаллергенные свойства: Накрытие драгоценными металлами, такими как Rhodium, может создать барьер, который предотвращает кожные реакции из базовых металлов.

Общие применения в пронзительных украшениях:

- Золотые украшения: Идеально подходит для создания роскошной эстетики без стоимости твердого золота.

- Родий: Обычно используется на серебряных ювелирных изделиях, чтобы улучшить блеск и предотвратить запятнание.

PVD -покрытие (Физическое осаждение пара)

PVD-покрытие-это передовая техника отделки, которая откладывает тонкую, прочный слой материала на ювелирные изделия в вакуумной среде. Он часто используется на украшениях титана и нержавеющей стали.

Ключевые преимущества PVD -покрытия:

- Исключительная долговечность: PVD -покрытие обеспечивает превосходное сопротивление царапинам, исчезающий, и коррозия по сравнению с традиционным покрытием.

- Яркие цвета: PVD может создать ряд потрясающих цветов, в том числе золото, черный, радуга, и розовое золото, без ущерба для качества.

- Экологичный и безопасный: PVD - это устойчивый процесс, который не включает вредные химические вещества, сделать его безопасным для окружающей среды и потребителей.

Почему он популярен в пронзительных украшениях:

Это обеспечивает длительную производительность, Сделать его идеальным для ювелирных изделий, которые носят ежедневно или подвергаются воздействию суровых условий. Это гипоаллергено, сделать его идеальным для клиентов с чувствительной кожей.

Сравнение трех методов

| Аспект | Полировка | Гальванизация | PVD -покрытие |

|---|---|---|---|

| Долговечность | Умеренный | Хороший | Отличный |

| Эстетическая привлекательность | Высокий | Высокий | Очень высоко |

| Сопротивление царапин | От низкого до умеренного | Умеренный | Очень высоко |

| Безопасность кожи | Высокий | Хороший (зависит от материала) | Отличный |

| Расходы | Низкий | Умеренный | Выше (Но экономически эффективная долгосрочная) |

Почему это важно для импортеров, Оптовики, и студии

Для предприятий в пронзительной ювелирной индустрии, Отделка поверхности - это не только эстетика, но и является ключевым фактором удовлетворенности клиентов и лояльности бренда. Высококачественная отделка может:

- Построить доверие: Плохо законченные украшения могут привести к негативным отзывам и возврату, повреждая вашу репутацию.

- Сократить расходы: Прочная отделка означает меньше замены или ремонта, Экономя деньги в долгосрочной перспективе.

- Выделяться: Предлагая уникальные отделки, такие как украшения из радуги, покрытые PVD, могут дифференцировать ваш бренд на конкурентном рынке.

Опыт Sensagem в отделке поверхности

Это Сенсагем, Мы специализируемся на предоставлении высококачественных пронзительных украшений с исключительной поверхностной отделкой.

Что мы предлагаем:

- Продвинутые методы: Мы используем современное оборудование для полировки, гальванизация, и PVD -покрытие, обеспечение безупречных результатов.

- Настройка: От золота до радужных PVD -покрытий, Мы можем создать отделки, адаптированные к стилю вашего бренда.

- Гарантия качества: Каждое произведение проходит строгое тестирование, чтобы соответствовать самым высоким стандартам долговечности, безопасность, и эстетика.

- Материал: Наша команда специализируется на нержавеющей стали и титане, обеспечение совместимости с расширенными методами отделки.